The first observation is that these variations appear in the extension of the dies during extrusion.

The second observation is that the new material used is much more viscous than the materials usually processed on this production line.

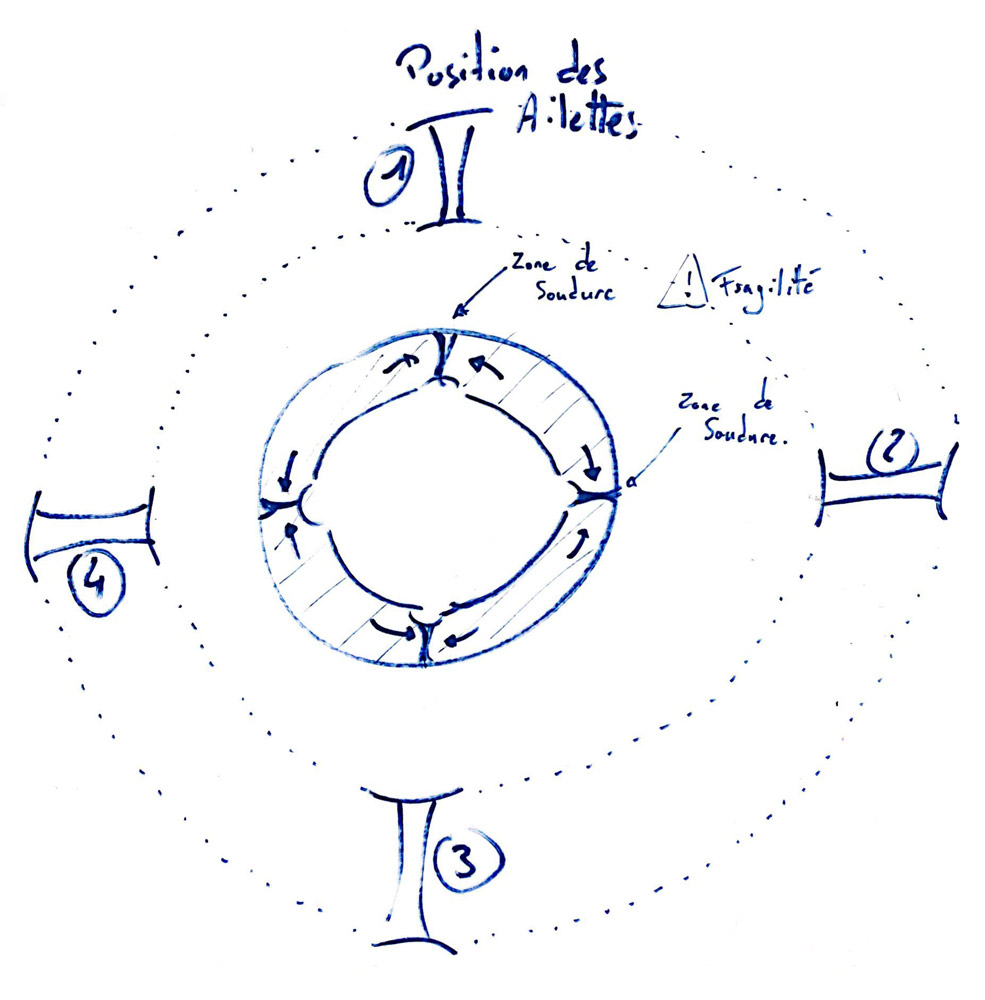

This type of flow defect is often due to the design of the die. In these cases, the tube is produced on an extrusion line equipped with a four-outlet die. Other outlets support the main flow and the pin. It is then clear that the design of the outlets disrupts the flow of the new material.

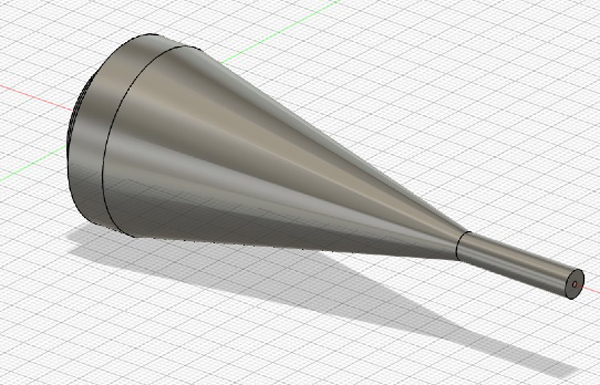

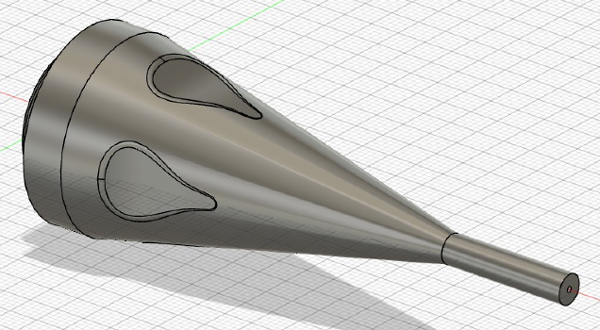

To correct this thickness variation in the tube section, it is necessary to reconsider the flow path design of the material.